More sustainability for cutting tools.

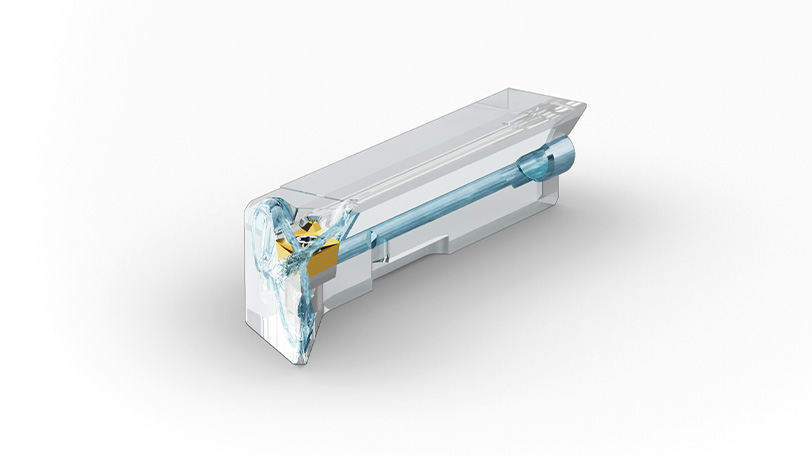

The tool manufacturer ARNO Werkzeuge, Karl-Heinz Arnold GmbH is presenting innovative clamping holders with internal cooling for cutting inserts that combine the best of both worlds. In a hybrid manufacturing process, the manufacturer combines additive technology with classic CNC milling. The result is clamping holders for tool holders that last longer and promise better surfaces because the coolant is guided directly to the cutting edges without obstructing the chip flow. A contribution to greater sustainability.

"Our innovative hybrid production in the manufacture of clamping holders for cutting tools with targeted internal cooling for turning operations combines the best of both worlds," emphasises Werner Meditz, Technical Director at ARNO Werkzeuge. The comparatively simple shanks of the new turning toolholders are milled using a conventional CNC process. This is because the inner cooling channel usually only consists of a simple hole. The head area of the holder, on the other hand, is applied directly to the shaft using a 3D printing process. In the SLM process, metal powder is melted layer by layer using a laser beam. "This gives us completely new design freedom," says Meditz. For example, the shape and geometric design of the cooling channels can be precisely organised so that the coolant is guided through the holder to the cutting tool with maximum efficiency and reaches the cutting edge directly from above and below. This enables the free surfaces to be cooled in a way that was previously not possible. At the same time, the necessary superstructures on the top of the head can be reduced to the minimum required. The chip breaks as desired and is optimally removed.

The best for users - even at the expense of sales

After production, the new clamps are hardened to the desired target hardness. This is followed by the targeted finishing of certain areas that require the highest standards of accuracy of fit and surface quality. After this, the clamp made from the two processes is as if cast from a single mould. This also has an effect on the surface quality in the application, as there is practically no vibration during machining.

The combination of conventional production with milling and the additive process has also proven to be the most economical option for manufacturing the clamping holders with efficient internal cooling. In everyday practice, the cutting inserts have proven to be extremely durable. In initial tests, the service life was easily doubled compared to previously used variants with internal coolant supply. "Of course, this means we have to forego higher tool sales. But we want the best for our customers - the users. We are deliberately taking a different approach," assures Meditz.

For more process reliability and better surfaces

The hybrid clamping holders with internal channels for the coolant increase process reliability and improve surface finishes thanks to targeted cooling in the machining process. ARNO Werkzeuge manufactures the new toolholders together with Kofler, thus making an effective contribution to greater sustainability in cutting tools.